Every now and then, air conditioners stop functioning. This may be due to a failure of a single component that is a crucial part of the whole system.

Some of our clients in Sydney have requested that I post brief notes on various reasons for air conditioning failure. In this blog I will describe the different parts of air conditioners that can cease to work and possibly sabotage the functionality of the entire system. When you read this article, think of it as a brief list of items that could possibly fail in direct expansion air conditioning system, by no means is it an exhaustive list, it is based on a ducted, direct expansion refrigerant system and one that does not take into consideration different types of units such as water cooled either by chiller or by cooling tower, and etc. Let’s see how a direct expansion air conditioning system works:

Cooling Heating

Click on th e picture to expand.

e picture to expand.

Let’s begin our little excursion on the

Indoor evaporator air conditioning unit:

Indoor unit/evaporator consists of: 1. Fan motor, which in turn includes:

1. Fan motor, which in turn includes:

- Bearing;

- Blade;

- Electrical overload/thermal;

- Motor.

2. Capacitor; 3. Contact; 4. Circuit breaker; 5. The expansion of valves includes:

- TX;

- Piston.

6. Controller; 7. Relative humidity sensor; 8. Temperature sensor.

Let us carry on to the

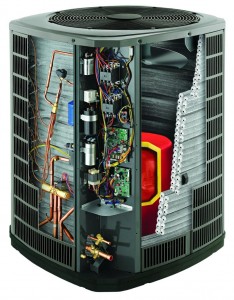

Outdoor condenser air conditioning unit:

So, what does outdoor unit/condenser have inside? 9. Fan motor, consisting of:

- Bearing;

- Blade;

- Electrical overload/thermal;

- Motor.

10. Controller; 11. Overload; 12. Circuit breaker time delay; 13. Defrost board; 14. Compressor contact; 15. Compressor overload; 16. Compressor circuit breaker; 17. Compressor capacitor; 18. Low pressure protection device; 19. High pressure protection device; 20. Reversing valve coil. Refrigerant system21. Refrigerant leak

| Indoor unit/evaporator |

Outgoing unit/Condenser |

||

| 1 | Refrigerant coil | ✓ | ✓ |

| 2 | Flared connection | ✓ | ✓ |

| 3 | Reversing valve | ✓ | |

| 4 | Service ports suction | ✓ | |

| 5 | Discharge | ✓ | |

| 6 | Expansion valve | ✓ |

Possible locations of air blockages22. return air filter 23. evaporator coils 24. condenser coil 25. supplier return air flexible ductwork crushed or dislodged 26. balancing equipment on supply air

To repair or replace, “that is the question? To put it simply, there is no correct answer. Below are a number of considerations to take into account before making a decision:

- How old is the system and is it still under warranty?

- What is wrong with the system?

- Have you got fusion insurance?

- Has one or more items failed previously?

- Has the failed item damaged other components (electrical damage may not be visible or evident at the time of a repair)?

- If multiple items have failed, replacing one item may only identify another item that has failed and also requires replacement before the system will run. (This is called a cascade failure)

- A cascade failure may have occurred at a single time, or may occur over a period of time as items damaged by the original failure, cease operating. (Intermittant fault)

- Was there a storm recently?

- Are you located in a poor power supply area?

Air conditioning “effective” life expectancy Industry bodies have identified the “effective” life expectancy, of any unit: Economic life of equipment

| Equipment | Economic life (years) | |

| Air conditioning unit – Package (10 kW – 100 kW) |

10 to 15 |

|

| Air conditioning unit – Room type |

7 to 10 |

|

| Air conditioning unit – Split units (up to 10 kW) |

7 to 10 |

|

| Air conditioning unit – Split package (10 kW – 100 kW) |

10 to 15 |

|

| Air filters – Dry media disposable |

6 to 18 months |

|

| Air filters – HEPA |

1 to 5 |

|

| Air filters – Kitchen hood grease filters (monthly clean) |

3 to 6 |

|

| Air handling unit – Custom built central station |

20 to 30 |

|

| Air handling unit – Proprietary line central station single or multiple zone |

20 to 25 |

|

| Automatic controls and instrumentation |

20 to 25 |

|

| Boilers – Cast iron |

25 to 30 |

|

| Boilers – Finned copper tube heat exchanger |

20 to 25 |

|

| Boilers – Fire tube |

15 to 20 |

|

| Boilers – Water tube |

20 to 30 |

|

| Boilers electrode |

15 to 20 |

|

| Coils to Cooling and heating |

20 to 25 |

|

| Cooling towers |

10 to 25 |

|

| Ductwork and fittings |

20 to 30 |

|

| Electric motors |

20 to 25 |

|

| Electric storage heaters |

20 to 25 |

|

| Electric strip heaters |

8 to 12 |

|

| Electrical final circuits and outlets |

20 to 25 |

|

| Electrical mains cables |

25 to 30 |

|

| Electrical switchgear and distribution equipment |

25 to 30 |

|

| Fans |

15 to 20 |

|

| Fire alarm systems |

20 to 25 |

|

| Gas convection heater |

15 to 20 |

|

| Generators – Diesel |

15 to 20 |

|

| Generators – Electric |

15 to 20 |

|

| Heat exchangers |

20 to 25 |

|

| Kitchen equipment |

15 to 20 |

|

| Laundry equipment |

15 to 20 |

|

| Lighting equipment |

20 to 25 |

|

| Pipe work and valves |

20 to 25 |

|

| Pumps |

20 to 25 |

|

| Radiators – Hot water |

20 to 25 |

|

| Refrigeration chillers – Absorption |

20 to 25 |

|

| Refrigeration chillers – Centrifugal |

20 to 25 |

|

| Refrigeration chillers – (Reciprocating, screw) |

15 to25 |

|

| Tanks |

20 to 30 |

|

| Variable air volume – Terminal units |

15 to 25 |

|

Table above taken from AIRAH. Within this timeframe is calculated that replacing of component is more economical than replacement of the unit. Beyond this timeframe it is calculated the replacement of the unit is more economical and replacement of the component. The “effective life expectancy of a unit” takes into consideration:

- Warranty;

- Component lifetime expectancy;

- Possible tax write-offs of capital;

- Cascade failure of components etc.

A failure of any one of the above 32 items will render the system inoperable. The job of a good service technician is to identify which of these components has failed, and then possibly replace it. The job of preventative maintenance is to extend the life of the 26 items and identify items that require replacement prior to their failure, to minimise downtime or loss of effectiveness. Most of the mechanical failures of the items above can be a lot cheaper than the replacement of the existing air conditioning system.

02 9938 6599

02 9938 6599